Steam Jet Refrigeration

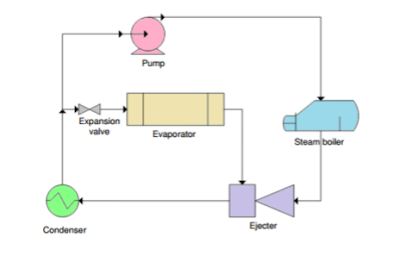

The steam-jet refrigeration system could be defined as a thermally drive compression

system in which vapor is compressed in a jet apparatus. An example of this operation

illustrated in Figure 6.

Steam is generated at pressure p1 in boiler and the mass flow rate is m1. By using the

nozzle, the steam is expanded to the pressure p0 prevailing in the evaporator, then it would

mixed with the steam from the evaporator in the mixing chamber. After that, the pressure

of the two streams is raised to the condensation pressure in the device called diffuser.

Virtually, all the kinetic energy is transformed into the pressure. When the heat is withdrawn

in the condenser, the steam will condenses.

The condensate is separate into two sub streams and it’s delivered to the steam boiler by a

driven force from a pump. Thus, one of the mass flow rate stream is led to the evaporator

through an expansion valve. Here, the sub stream evaporates and absorbing the heat, and

then exiting expanded steam, moving at a higher velocity, sucks this stream into the mixing

chamber.

Water, mainly employed as a working steam and also as refrigerant in the steam-jet

refrigeration system. It is a low-cost, free of hazard, having a high specific enthalpy of

evaporation. The pressure p0 operates usually between 0.6 until 1.2 kPa, while pc operates

between 3 until 8 kPa, depending on the cooling-water temperature.

The steam-jet refrigeration is suited for many applications such as :

1. Direct vaporization for heat-sensitive foods and chemicals drying. Mostly, for

preservation of the product quality.

2. Absorption of gases like CO2, SO2, ClO2 in chilled water.

Assuming the water greater than 35°F is needed and that water and stream costs are

reasonable, there are several advantages of steam jet units that could be achieved

following :

1. No moving devices, except the pumps.

2. Low pressure system.

3. Compact design and could be installed on the outdoors.

4. Economical process, since the cooling water and steam could easily be adjusted.

5. Low maintenance and Vibration-free.

6. Simple start up and operation.

7. Cost per ton of refrigeration is relatively low.

Comments

Post a Comment